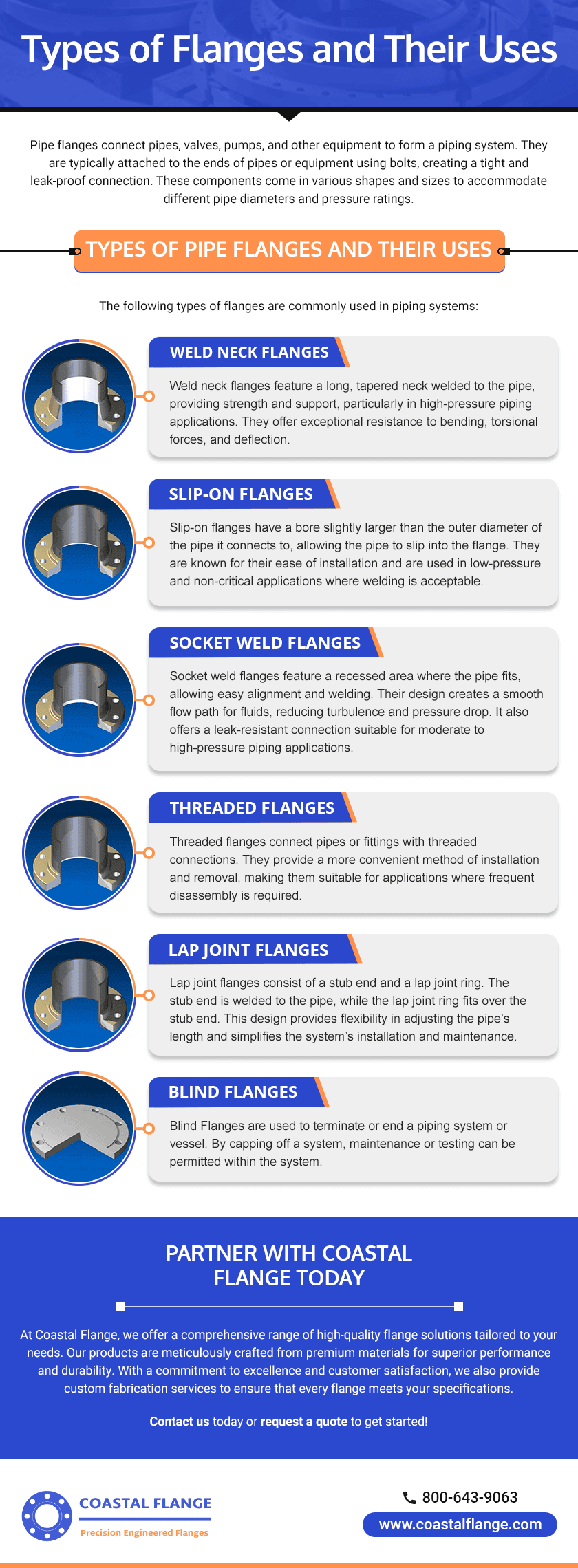

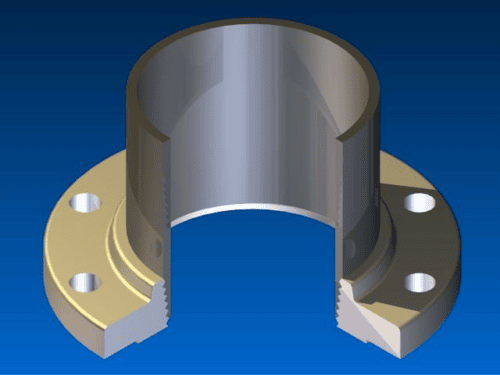

Pipe flanges connect pipes, valves, pumps, and other equipment to form a piping system. They are typically attached to the ends of pipes or equipment using bolts, creating a tight and leak-proof connection. These components come in various shapes and sizes to accommodate different pipe diameters and pressure ratings.

In this article, we will examine the different types and applications of flanges used in piping and the key considerations in selecting the right component.

Key Considerations in Pipe Flange Selection

Here are several factors to take into account when choosing the right flange type for piping:

Operating Conditions

Temperature, pressure, and fluid type are crucial in determining the right flange type and material. For high-pressure or high-temperature applications, weld neck flanges are preferred due to their superior strength and resistance to deformation. Similarly, corrosive fluids may require pipe flanges made from corrosion-resistant materials such as stainless steel or alloy steel.

Material Compatibility

The chosen material must be compatible with the fluid or gas being transported. Ensuring compatibility enhances the longevity and reliability of the piping system and mitigates the risk of leaks, failures, and costly downtime. Therefore, thoroughly evaluating material properties is essential to making informed decisions in pipe flange selection.

Flange Standard

Different industries may require adherence to specific standards, which dictate the flanges’ dimensions, materials, and performance requirements. For example, oil and gas industry piping applications often require flanges that adhere to ASME B16.5 or API 6A. On the other hand, pharmaceuticals or food processing may require flanges made from materials that meet stringent hygiene standards.

Size and Dimensions

Properly matching the size and dimensions of the flange to the pipe helps maintain structural integrity and prevent leaks. The dimensions of the flange including its outer diameter, inner diameter, and bolt-hole pattern must align with the piping system’s specifications. Additionally, considering factors like flange face type (raised face, flat face, or ring type joint) and thickness is vital to ensure compatibility.

Cost-Effectiveness

Different flange types vary in cost due to their materials, design complexity, and installation requirements. For instance, weld neck flanges are expensive upfront but offer better structural integrity and reduced maintenance costs over time. Meanwhile, slip-on flanges are often more cost-effective due to their simple design and ease of installation.

Choose Coastal Flange for High-Quality Flanges

At Coastal Flange, we offer a comprehensive range of high-quality flange solutions tailored to your needs. Our products are meticulously crafted from premium materials for superior performance and durability. With a commitment to excellence and customer satisfaction, we also provide custom fabrication services to ensure that every flange meets your specifications.

Contact us today or request a quote to get started!